The design concept and structure of the fully immersed buried power transformer produced by our company are completely different from those of other domestic and foreign companies. The specific characteristics are as follows£º

¡¾Technical Standards¡¿

The company's buried (underground) transformer technology originated in Germany, after recent years of technological upgrading, its technical parameters have far exceeded the relevant German standards. The supply transformer capacity is 50 ~ 1250KVA three-phase transformer and single-phase transformer of street lamp system.

1. The company's buried transformer does not need pit protection. It breaks through the traditional design of oil-immersed transformer in design, focusing on temperature rise control, short-circuit resistance and transformer heat dissipation. The top oil temperature is controlled below 45K, far below the national standard of 60K.

2¡¢The core of transformer is high magnetic conductivity and cold-rolled grain oriented electrical silicon steel sheet. The core is designed with plane section and its performance level is S11-S13.

3¡¢The transformer body adopts R-type coiled core structure, which improves the utilization ratio of iron core section, effectively reduces no-load and load loss, and has strong mechanical strength. Because the iron core is seamless, the factors causing noise are eliminated. In short-circuit resistance, the coiled core transformer eliminates the secondary utilization of silicon steel sheets, and the whole body is dipped in paint. Quality assurance of electrical performance and service life, to achieve maintenance-free state.

4¡¢The underground transformer of our company adopts submarine cable sealing technology, which can meet the conditions of long-term underwater operation.

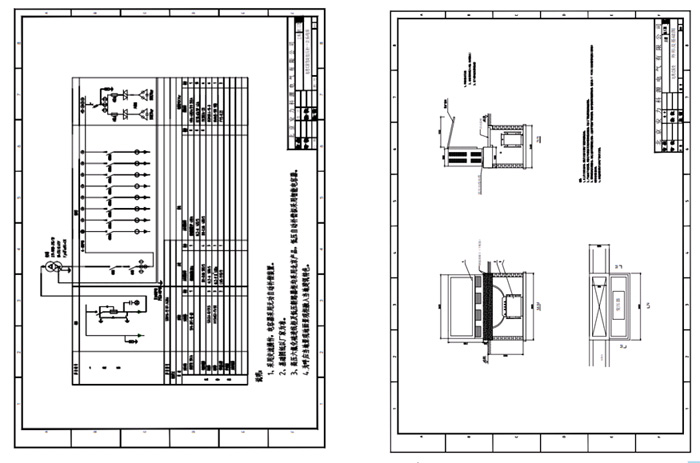

5¡¢Transformer factory is equipped with in and out cables, to the scene directly access to high and low voltage ground cabinet, easy to install.

6¡¢The low-voltage side of 630-1250 kVA underground transformer can be equipped with 2-4 cables to meet the current requirements.

¡¾Anti-corrosion ¡¿

The company's underground transformer adopts the nano-penetration anti-corrosion technology of zinc-chromium composite coating developed by the Institute of Antisepsis of the Chinese Academy of Sciences. The anti-corrosion performance is three times higher than that of hot-dip galvanizing and hot-dip aluminium, and the service life of the shell in water can be increased to more than 30 years.

¡¾Cable¡¿

The buried transformer is equipped with 5 meters long incoming and outgoing wires and cables in the production plant. When installed, it is directly connected to the high and low voltage side of the ground distribution cabinet. This not only facilitates installation, but also greatly improves the product protection standard. The overall product meets IP68, and truly meets the requirements of long-term underwater work of the transformer.

When the transformer cables are loaded into the transformer body, they first enter the transformer sub-box, which is equipped with stress relief devices, cable locking system and high-strength flexible insulation sealing materials. This measure can prevent the cable from being damaged when it is pulled by external forces. Underground transformer adopts submarine cable sealed lead technology, which meets relevant international standards in demagnetization, anti-corrosion, waterproof and other aspects.

¡¾Heat dissipation¡¿

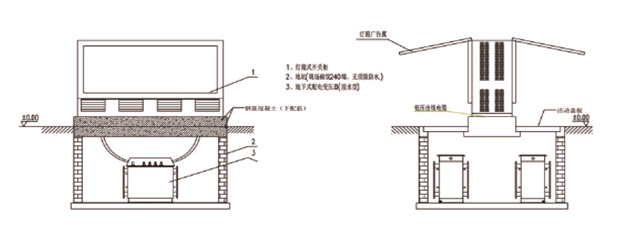

The buried transformer is installed in the relatively closed, humid and poorly ventilated underground space, and its operation conditions are bad. The company's buried transformers are water-operated products, which do not need to be sealed pits, nor need to be waterproof. Rainy and high water level in the South and coastal areas provide a good environment for transformer operation.

The buried transformer uses microcirculation catheter technology and flat panel radiation for heat dissipation, and all imported naphthenic transformer oil to enhance fluidity, which can better meet the requirements of the vast external environment in China without regular maintenance.

¡¾Ground High and Low Voltage Distribution Cabinet and Billboard ¡¿

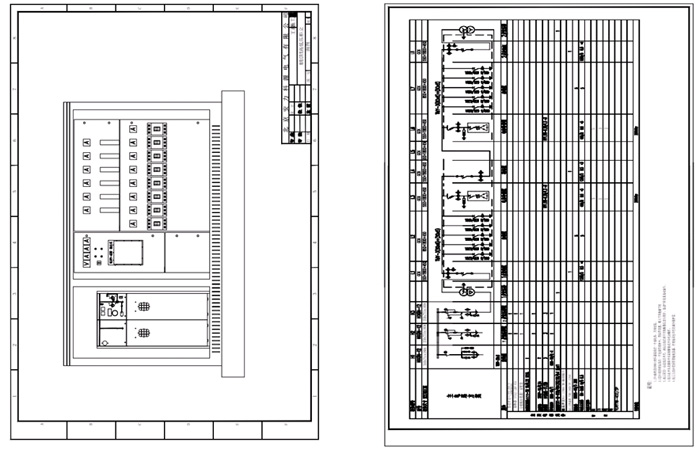

The outer shell of outdoor distribution cabinet is made of stainless steel. The cabinet includes high-voltage switch, low-voltage distribution device (including compensation), which can realize high and low voltage measurement function. The primary system is made according to the specific requirements of users. The billboard of the light box is equipped with LED light-emitting elements which are beautiful, energy-saving and environmental-friendly, and can be used for commercial advertisement.

When several buried transformers are installed in the residential area, the high voltage can also be supplied by the ring cabinet. Each circuit is protected. The low voltage side can also be directly connected to the building without outdoor low voltage cabinet.

Reliable wall installation of ground landscape distribution cabinet can also be installed on the street. Advertising boards can be set up or not, and light box billboards have street lamp control functions.

¡¾Unique overall design¡¿

The company's buried box is designed with the idea of break up the whole into parts. Transformers are permanently placed underground, and only landscape light box distribution equipment is left on the ground. When installed in the district, high-voltage and low-voltage cabinets can also be placed separately without occupying precious landscape green space.